Home > Posts

What is Rapid Tooling?

qingdao reach, reach industry, benefit, reach injection, reach mfg, design for manufacturing, rapid tooling, fast turnaround, design, wall thickness, rib, boss, vent placement, mold making, tooling, engineering, part design, reach-mfg, dfm, plastic injection, injection, rapid, quick turn tool, rapid mold,

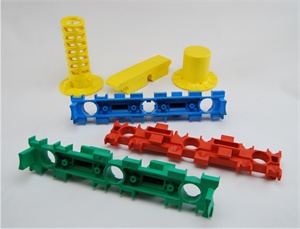

How Plastic Parts Get Colored

qingdao reach, reach industry,benefit, reach injection, reach mfg, design for manufacturing, rapid tooling, fast turnaround, design, wall thickness, rib, boss, vent placement, mold making, tooling, engineering, part design, reach-mfg, dfm, plastic injection, injection, rapid, quick turn tool, rapid mold,

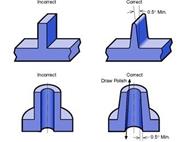

Plastic Part Design

The process ofplastic injection moldingis designed to produce precision parts at a low cost. The part design must be developed to maximize the efficiency inherent in high-volume molding. With the right design, parts can be consistently made with quality. Without a good design, costly pro

Plastic Part Design For Manufacturing

There are key factors that go into making a high-quality plastic injection molded part: part design, tool making, material selection and manufacturing.Here we will start the beginning of the process: part design.Without a good design, costly processing mistakes can be made. The process ofplast

Injection Molding Terms

Injection Molding TermsThere are hundreds of injection molding terms used in the industry. We have chosen to highlight the most common nomenclature used when discussing Rapid Tooling andInjection molding parts, materials and problems. Additives– These compounds are added to resin

What’s the Best Way to Make a Plastic Prototype?

What’s the Best Way to Make a Plastic Prototype?Tooling forplastic injection moldingpresents a formidable barrier to any team needing a plastic prototype or a few parts for prototype testing and evaluation.For one, the price tag can run into six figures. But lead time is often an

Making a Prototype

Before 1880, every inventor had to present a working model or prototype of his or her invention to the patent office as part of the patent application. You do not have to submit a prototype anymore, however, prototypes are great for several reasons.Legally a prototype proves what is called a &

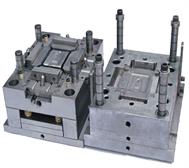

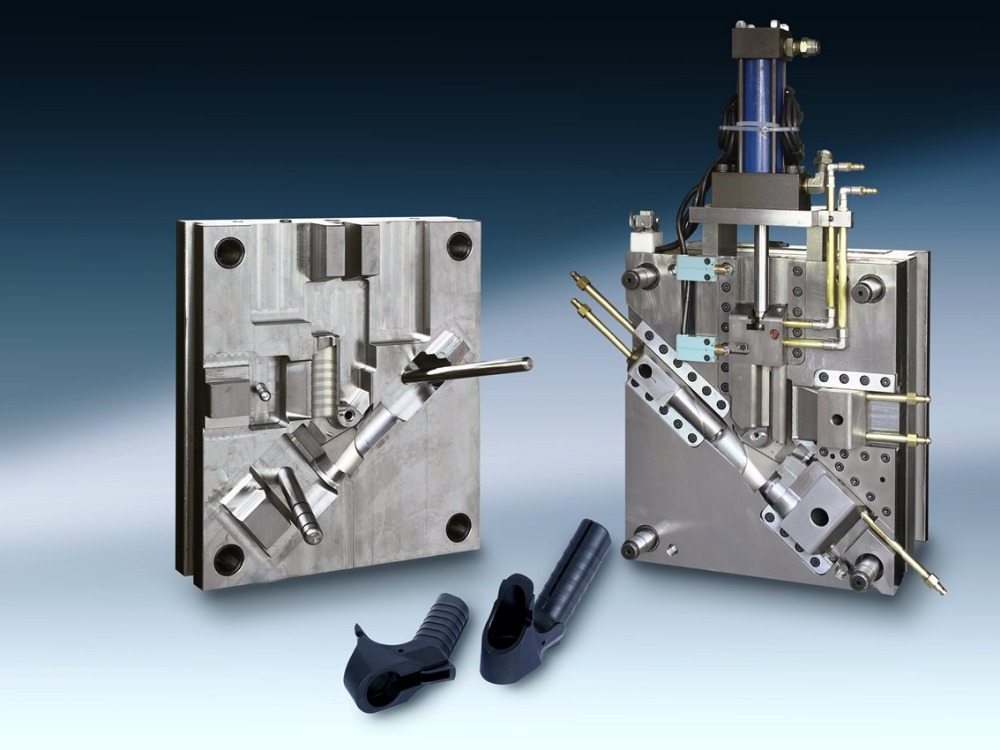

What Is Injection Mold And Why It Is Important

Injection molding is a manufacturing process widely used for producing items from toys and plastic trinkets to automotive body panels, water bottles, and cell phone cases. A liquid plastic is forced into a mold and cures - it sounds simple, but is a complex process. The liquids used vary from hot gl

The Difference Between Hot and Cold Rolled Steel

To meet unique application needs, there are many different types of steel available, in various shapes, sizes, and finishes. Fully understanding the unique properties and benefits of each type can allow for significant time and cost savings while helping to ensure optimal quality and performance of

Thermoplastic VS Thermoset Resins

Thermoplasticpolymerresins are extremely common, and we come in contact with thermoplastic resins constantly. Thermoplastic resins are most commonly unreinforced, meaning, the resin is formed into shapes and have no reinforcement providing strength.Examples of common thermoplastic resins