★7-25 days for Rapid tooling making & Short Term Plastic Injection Molding

★Consistent quality parts

★No restriction on tooling construction

★Free Quote and Detailed DFM Provided & Inspection within hours

Plastic Injection Molding Service

REACH’s injection molding capabilities range from pilot production quantities through production quantities, Rapid tooling, multi-cavity production tooling, tight tolerances, over-molding, inserts installing and secondary operations, we could fast deliver high-quality plastic injection parts within your budget.

Injection molding is a great process for low volume to high volume production manufacturing. It is widely used in the medical, automotive, industrial, construction and consumer product industries. It’s great if you need small quantities on a regular basis or if you want to bridge the gap between the prototyping stage and full-scale production. REACH specializes in Rapid Tooling(prototype mold/rapid tooling) making low-medium volume production in injection molding that would meet your different needs.

Rapid Tooling Service

Quickly deliver injection molding sample parts in 1-4 weeks!

REACH provides rapid tooling for customers who need production-grade injection molded parts in short order. For our customers who cannot wait 5-10 weeks for traditional or offshore tooling to be made, Reach Machinery offers Rapid tooling and injection plastic parts to help support. Customer’s Parts has no geometry limits on part dimensions and allows the most available material and surface finish.

With press sizes ranging from 20 tons to 800 tons, we can meet your injection molding part needs from 25 parts to high-volume production runs. Learn more about our Rapid Tooling service.

Production injection molds and parts

Except for our core business Rapid Tooling, we also provide high volume production tooling and export tooling to customers. Contact us if any questions.

Base info for an RFQ

Our international team will listen to your demands, and will offer the best solution to provide quality parts in a fast manner within your budget.

If you could provide the below info, it would be easier for us to get you the exact pricing.

3D file, 2D file(if available), Material, Finish, Color, Qty: T1 / Batch, Inserts, printing, etc.(if available)

Process:

Project kicked off(3D, material, finish, color, qty)—DFM approval—Mold Making—Mold Try out—Inspection—Package.

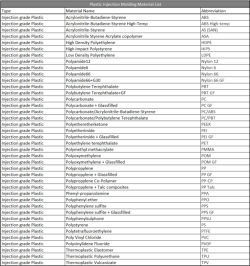

Most of the thermoplastic resins are available in Reach Machinery for many different applications. Below are some thermoplastics that we frequently use for customers. Contact us to get a detailed material list with material grades we normally used for our customers!

| ABS | LDPE | Nylon66 | POM | TPE |

| PC/ABS | HIPS | Nylon6 | PVDF | TPU |

| PC | HDPE | PMMA | PP | TPV |

| PC/PBT | PS | AS | PPTalc | PET |

| PBT | PTFE | Nylon66GF | PVC | ASA |

| PPO | PEI | PPS | PPA | PEEK |

Exotic materials and special requests can be purchased or imported if required. Please kindly ask us when in doubt.

We order most of the materials directly from the material manufacturers, Tier one or Tier two distributors to ensure the material is genuine and traceable, material certs and associated documents are available for each order.

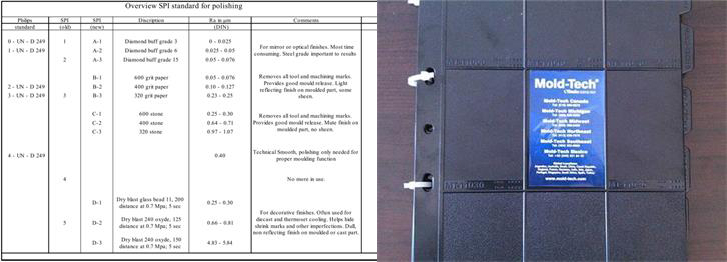

The surface finish on the tools is no limited. We could apply different finish per SPI finish grades, VDI finish grades, Mold Tech Texture finish for mold according to your request. Moreover, we could apply painting, printing and plating to the plastic parts. Below are some finishes our customers usually used for their parts.

High gloss finishes: A1, A2, A3, plastic mirrors, lens and other optical plastic goods.

Semi-gloss finishes: B1, B2, B3, better finish for demolding, semi-gloss finishes with some sheen.

Low gloss finish: C1, C2, C3, mute finish on molded part, no-sheen, for non-cosmetic parts.

Matte finishes: D1, D2, D3, sandblasted the mold to gain decorative, non-reflective finishes on parts.

Equivalent textures are available and often provide an excellent comparison to the actual Mold-Tech textures and SPI standards, while saving significant cost and mold build time. The use of an equivalent texture should be determined and decided by the customer. Below list the MT texture our customer normally used.

Texture Number Min. Draft Required

11000 1.5

11010 2.0

11020 3.0

11030 3.5

11050 7.0

11100 9.5

If you need a specified texture, just let us know and we will handle it. Applying texture onto the mold would require draft on the side surfaces, otherwise, scratch marks will occur when the part is demolded, if you need more info, please Contact us for more suggestions.

If you have a Pantone/RAL color code, there is no problem to color the material and run parts, and we could also do color according to the customer’s color sample, even a Tint color sample.

We will provide DFM analysis to help support the design to the manufacturable, forecast the potential issue and provide suggestions to improve and eliminate the issue. For complex, we will provide Mold Flow analysis to help eliminate the potential issues and improve the quality of the parts in advance.

Contact us to get Design tips for you to make your design easier for manufacturing and lower down the cost of manufacturing. Of course, we are always online to help support your project development, send us the file today for review.

This includes all the machining processes for tooling making. We will follow up with the process and keep you updated and aware of everything.

CNC-rough machining-water line-electrode-EDM-polishing-texturing-grinding-fitting-mold clamping-mold try out

We would set up the tool properly, dry the material, connect the waterlines, control the mold temperature, process the material and run the samples correctly according to the material spec sheet. Below is a simple process to show how injection molding works.

1. The plastic resin comes in raw pellets and would be mixed with the pigments/color masterbatch, and which will be dried to the right moisture content for try out.

2. The dried material will be loaded into the hopper of the injection press machine, the screw inside the barrel will screw forward and the material will be transferred, the material will be heated and sheared into a fully molten liquid resin.

3. Mold temperature is increased and will close automatically, the press will inject the liquid resin into the mold cavity and start packing afterward.

4. The mold’s temperature helps cool and solidify the plastic part inside the mold.

5. When the part reaches the appropriate temperature, the mold will open and will eject the part off the mold. And start a new cycle.

Inspection, Tolerance, Package.

All the parts will be inspected according to our quality control plan.

Unless otherwise specified, we comply with the DIN 16901 standard tolerances for plastic injection moldings(equivalent to SPI tolerance commercial standard.).

Strong Package will be used for all the parts and ensure parts will not be damaged during shipment. We could package according to specified requirements.

More capabilities:

Overmolding

Insert molding

Insert installing(Mold-in, heat stake, post-install)

Ultrasonic welding, laser welding(plastic)

Pad printing, screen printing, foils stamping,

Painting, soft-touch painting

Plating

Balancing testing, Airflow testing, Breakage testing, Noise testing,

REACH always make it easier for the customer to gain quality parts as expected in a fast manner within budget!

Start Your Projects with Free Quote Today