●6-8 days to get parts upto 200 pcs

●Ability to hold tight tolerance

●Integrated manufacturing abilities

●Variety of finishing

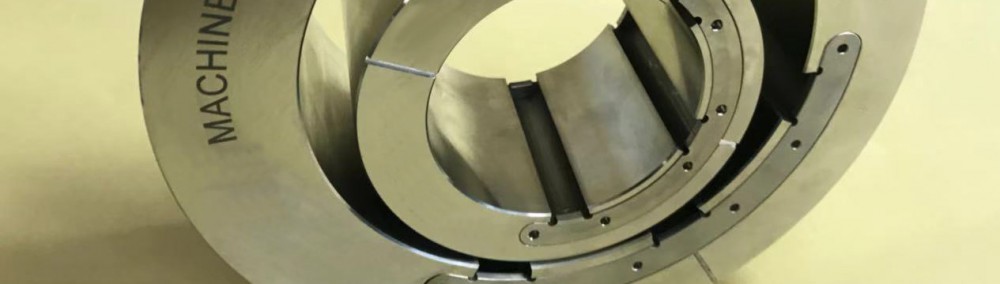

CNC Machining Service

Reach Machinery specializes in CNC machining using a wide range of plastic and metal materials, provides a variety of CNC machining services including milling, turning, EDM, wire cutting, grinding and far more.

CNC Start with a solid block of production grade plastic or metal that is clamped into place in a CNC mill and start cutting away the material to reveal a final design that has been pre-programmed into the CNC machine. CNC Machining is a great process for manufacturing low and high quantities of quality metal and plastic parts and which look and feel like production made parts. CNC machining is a very fast and accurate method to make your design into a reality.

CNC machining services including milling, turning, EDM, wire EDM and precision CNC milling centers, with the machines’ help, we can meet your needs for high precision CNC machined parts.

CNC Machining Advantage

1. More precise. CNC machines are programmable and every detail of the production process can be fed into the machine, identical parts can make with the highest accuracy levels. Programming the specification and designs into the machine leaves less room for mistake.

2. Greater Efficiency. We are capable of automatically switching tools for each stage of the process, and can operate simultaneously on multiple axes, saving valuable time and energy.

3. Fast Turn-around. We can provide a quote within 24 hours and 6-8 days machining lead time or less for about 200 parts

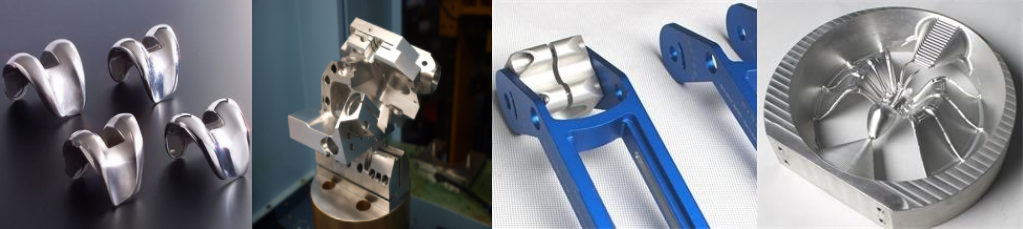

4. More options. we could use wide range of material for CNC machining and could achieve variety of finishing.

CNC Milling Service- To Meet Quality Standards

The process of CNC milling involves a procedure that cuts materials into precise sizes and shapes through the use of precision rotary cutters. Computer numerical control (CNC) is a modern technological marvel that produces high precision milling. The high level of accuracy is ensured by the computer-controlled elements of the system.

We have a good understanding of what our customers need for sustainable success. We have the capability to consistently meet your production targets, on time and within the agreed budget.

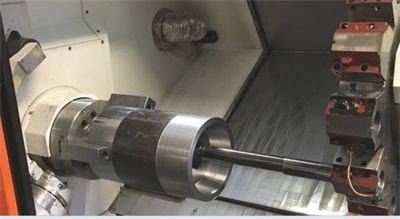

CNC Turning Service- Fast, Accurate, Alternative

The process of CNC turning involves the use of a cutting tool, often a non-rotary tool bit, which is applied to a rotating workpiece in order to eliminate material and produce precise steps in diameters for the creation of a shape. The process can be executed manually with a lathe. However, it is commonly done today through use of a CNC machine. We understand the importance of meeting production targets and ensuring that every order is delivered on schedule. CNC turning is a rapid process that means we can create large numbers of well-finished components in a relatively short space of time. If you need high volumes and/or have a tight time scale, we’ve usually got the capability to meet your needs.

CNC Machining Material

Material | Grads | color | Material type | Features and characteristics |

Aluminum | 5052 | Natural | Soft | l Improved corrosion resistance over 7075 l General purpose aluminum with Medium strength l Good formability, weldability l Contains magnesium and silicon |

6061 | Natural | Soft | ||

6063 | Natural | Soft | ||

6082 | Natural | Soft | ||

7075 | Natural | Soft | l Higher strength over Aluminum 6061 l Good fatigue strength | |

Brass | 260 | Natural | Soft | l Good corrosion resistance l Resistant to most chemicals l Plate stock |

Copper | C101 | Natural | Soft | l Oxygen-free electrical copper l High electrical conductivity l Good corrosion resistance in most environments l Weak against acids, halogens sulphides and ammonia solutions |

Steel | 1018 | Natural | Soft | l Plain low carbon steel l Good formability and weldability l Case harden only |

12L14 | Natural | Soft | l Excellent machinability l Case harden only | |

Stainless Steel | 303 | Natural | Hard | l Most commonly used stainless steel l Low carbon l Better weldability and formability |

304 | Natural | Hard | l Most commonly used stainless steel l Low carbon l Better weldability and formability | |

316 | Natural | Hard | l Increased corrosion and chemical resistance over 304 l Increased resistance to cracking and pitting | |

416 | Natural | Hard | l Free machining l Less corrosion resistant than 300 series l Can be heat treated | |

17-4 PH | Natural | Hard | l Higher magnetism than 304 and 316 stainless steel l Oxidation and corrosion resistance | |

Zinc Alloy | Zamak 3 | Natural | Hard | l excellent resistance to atmospheric corrosion and mechanical properties |

Titanium | Ti-6AI-4V | Natural | Hard | l Light-weight and high strength l High temperature and corrosion resistance |

Plastic | ABS | Natural/Black | l General purpose Nylon l Fair flame resistance and good machining | |

ABS/PC | Natural | l Excellent impact resistance and toughness l good chemical stability | ||

PC/Polycarbonate | Clear/Black | l High impact-resistance, good toughness l High temp resistance | ||

PMMA | Clear/Black | l Excellent Transparency l Good weather Resistance | ||

PA / Nylon66 | Natural/Black 30%GF | l General purpose Nylon l Fair flame resistance and good machining | ||

PP | Natural/Black 20%GF | l Flexible, excellent resistance to fatigue l Good chemical stability | ||

POM/Acetal/ Delrin | Black/White | l High stiffness, low friction l Excellent dimensional stability | ||

PVC | White/Grey | l Excellent chemical and corrosion resistance l Good flame resistance l Low cost | ||

HDPE | White | l Acid and alkali resistance, resistance to organic solvents l Good chemical stability and good mechanical strength | ||

LDPE | White | l Higher tensile strength, better puncture resistance and tear resistance | ||

PEEK | Muddy yellow | l Excellent dimensional stability, good impact strength l Stiffness an minimum levels of creep, better impact resistance l Excellent machinability | ||

PEI / Ultem 1000 | Amber | l Excellent mechanical properties, electrical insulation, resistance to radiation, resistance to high and low temperature and wear resistance l Good flame retardancy, resistance to chemical reactions and electrical insulation properties |

CNC Surface Finish

As Machined(standard) | ~125 RA µin (3.2 RA µm). Minor tool marks will be visible on the part. Surface finish requirements can be increased to 63, 32, or 16 RA µin. |

Bead Blast | Matte finish with light texture is achieved by blowing small glass beads against the part. |

Anodizing Type II | Corrosion resistant finish. A variety of different colors can be applied when anodizing. |

Anodizing Type III | Adds a wear resistant layer on top of the corrosion resistance of Type II. |

Powder Coating | Strong, wear and corrosion resistant finish, that is more durable than the methods mentioned above. Powder coat finishing are available in large range of colors. |

Other surface finishes are available upon request, for more please see our surface finishing services. | |

Tolerances

Our general tolerances for CNC machining of metals is DIN-2768-1-fine and for plastics DIN-2768-1-medium. Tolerances are greatly affected by part geometry and type of material. We will consult with you on every part of your project and will seek to provide the highest degree of precision possible.

CNC Machining Metal & Plastic parts samples:

Start Your Projects with Free Quote Today