If injection molding is a manufacturing process then how is it possible to process rapid tooling?

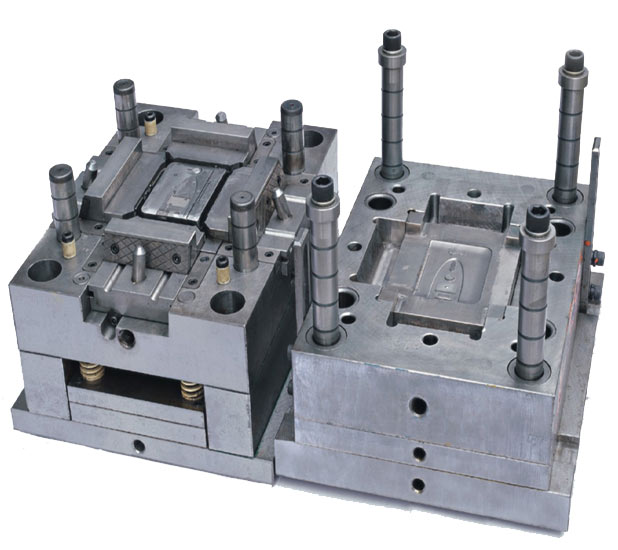

At REACH, we define rapid tooling as several hundred to several thousand pieces created from a single cavity, low-cost tooling within 1-3 weeks. Rapid toolings are made with the same manufacturing process as mass production but there are differences in the tooling and the processing of the parts.

Here are a few of the differences:

• The rapid tooling is not typically as robust as the final product. The tooling is often made from aluminum or softer steel/P20 steel in order to reduce both the material costs and the labor to make the tool. The tools are not designed for a high yield of parts, but sometimes it could run about 50k shots of parts if the tool could be maintained in the workshop at REACH.

• Rapid toolings are made to prove that the design of a part will work. The majority of the cost is in the tooling. The cost of producing the parts is relatively minor so almost no effort is put into the tool to make the parts run fast. In mass production, however, the focus is on the price of the piece. Getting the tool to make parts as quickly as possible lowers the cost of those parts. This change in focus can make significant changes to the design of the tooling. But there is no limit on the part design/tooling constructions, we could still make it, in a different way.

• Mass production focuses on cost, so the reduction of labor is critical. Mass producers can afford to invest in robots to handle parts coming off of a tool because, while the initial cost of the robotic equipment might be high, the cost will eventually balance out as large quantities of product are made. To make the small production with rapid tooling, it is quicker and cheaper to hand eject a few hundred parts from a tool than to spend time and money on automating a robot to make the tool.

Here are some reasons you would make rapid tooling before full production:

• The product is intended to be mass-produced in very large quantities. If this is the case then before you invest in expensive multi-cavity tooling (where one tool can produce 64 or more parts) you should make sure that the engineering is sound and that the product works as desired in its production materials. Producing a few hundred or a thousand rapid tooling for testing provides that assurance.

• You need to do consumer research before mass production. You should do rapid tooling in this case because your consumer research will be more compelling if the product you give your consumer researchers is as close as possible to the final product. Producing several hundred rapid toolings allows you to do a very accurate consumer test and also gives you the opportunity to make changes based on their input before mass production.

• Your product requires a significant amount of testing before it can be released to consumers. If this is the case, you want to test a prototype that is as close to the final product as possible. The materials and production method should be identical, and if the product is very complicated, mimicking the rapid tooling assembly allows you to fine-tune the assembly process before going into full-scale production.

• You want to show your distributors a finished part so they know exactly what they’re purchasing. Customers often won’t make a purchasing decision based on a sketch or partially formed idea, so rapid tooling will help prove your product’s validity and solidify sales.

The pricing of rapid tooling is often quite different than pricing for mass production. In mass production, you have two expenses: your tooling costs and your piece price costs. Setups and color changes are not a big deal in mass production because the costs get balanced out after a very large quantity has been produced. A few pennies in the piece price cost, however, can be a very big deal because even pennies add up quickly over the course of mass production. It is not uncommon for mass production costing to be calculated out to 4 or 6 decimal places in order to evaluate costs and make reductions of fractions of a penny.

In rapid tooling, we typically have a single cost for making the mold and the prototypes together(depends on the quantity of the parts, for parts, more than 25 pcs, we will quote to run small production). Unlike in mass production mode, however, changing colors or materials will have a significant effect on the cost because of the amount of time it takes relative to the short amount of time for producing a few hundred parts.

Producing a few hundred to several thousand plastic prototypes from rapid tooling can be a very helpful step to take before moving to mass production. It verifies part engineering, allows you to show consumers, distributors, and salespeople a definitive finished product, and offers you the opportunity to fully test the product before you invest in expensive mass production tooling.

REACH always make it easier for the customer to gain quality parts as expected in a fast manner within the budget!

Start Your Projects with Free Quote Today

info@reach-mfg.com