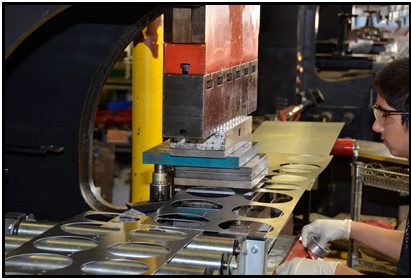

Stamped metal components form the building blocks of vehicles, equipment, electronics, appliances, tools, and so much more. Precision metal stamping processes employ a wide range of specialty equipment to cut, pierce, bend, and form sheet metal to meet modern needs.

Steel and steel alloys, brass, aluminum, and copper are all popular materials for stamping projects, and all often begin as simple sheets. Through metal stamping technology, these essential materials are transformed into either stand-alone, high-performance components, or pieces of larger, more complex assemblies.

Metal Stamping Processes

The processes and tools employed by metal stampers are nearly as diverse as the applications they serve. A few of the most common include:

· Progressive Die Stamping

· Blanking

· Piercing and Punching

· Coining

· Shallow Draw Stamping

· Laser Cutting and Water Jet Cutting

· Bending

· Forming

For most custom stamping projects, a unique finish or secondary machining process enhances a part’s lifespan and performance. Craft the ideal component with:

· Deburring

· Tapping

· Grinding

· Riveting

· Powder coating and plating

Electrical Components

Precision metal stamping serves a wide variety of applications and industries. Within the electrical and power industry alone, stamped metal parts serve countless needs across a wide variety of electrical components.

The absolute accuracy of reliable metal stamping proves critical to everything from the intricate components in automotive set-ups to large metal industrial housings. Clips, cups, covers, fasteners, and even sensitive electronic assemblies join the list of precision products made from detailed stamped metal parts.

Construction

Construction environments require durability. Harsh conditions, aggressive use, and high wear are all par for the course. Custom metal stamping combines accurate, repeatable manufacturing processes with these rigorous needs. Stamped parts are long-lasting, resist temperature strains, maintain integrity under the threat of rust or corrosion, and offer high strength alloy material choices for heavy lifting.

Metal stamping serves the needs of power tools, panel fastening systems, industrial switches and connectors, and even complex custom assemblies for construction projects.

Hardware

From doors, shelves, and cabinets to lighting fixtures and custom switches, stamped metal parts serve hardware needs both commercial and residential. Nuts, bolts, screws, hinges, and washers don’t even begin to cover the comprehensive list.

Specialty stamped hardware products include:

· Catches, latches, locks, and closer systems.

· Household tools.

· Power tools.

· Doors, handles, and cabinetry essentials.

· Mounting brackets and chassis.

· Custom quick connects and lighting components.

Fastening

The precision and durability of stamped metal components make for exceptional fastening solutions. Hooks, bolts, and even complex contact elements can all be stamped.

The range of capabilities and finishes available for stamped parts make for readily customized brackets, latch assemblies, and lock systems to fit tools, machinery, automotive projects, and more.

Appliances

Appliances encompass a dramatic range of sizes, shapes, finishes, and functions—both residential and commercial. This industry demands an equally complex suite of parts and components for a number of appliance types, including:

· Ice machines and freezers

· Microwaves, toaster ovens, standard ovens, ranges, and cooktops

· Refrigerators and refrigeration systems

· Grills and outdoor kitchens

· Trash compactors and disposal systems

· Fryers and griddles

The custom finishing solutions offered by metal stamping are an especially effective fit for appliance work. The resulting components perform with reliability, precision, and the appropriate polish for finished projects. To learn more about the specialty industries AIC serves, or to request a quote for your next project, contact us today.